On July 3, 2024, Jiangsu Ganfeng celebrated the official rollout of its 100,000th power battery system for engineering machinery as a brand-new unit was shipped from the workshop. "From 1 to 100,000," Jiangsu Ganfeng, as Ganfeng Lithium's production base for engineering machinery power batteries, has consistently focused on continuous innovation and reliable quality to give back to the market and customers, driving industrial electrification and green sustainability.

The 100,000th power battery system utilizes Ganfeng Lithium's independently developed active balancing battery management system (BMS) specifically for industrial vehicles. This product is the first of its kind in China to target the industrial vehicle segment with an active balancing BMS for systems below 100V. It features redundant batteries, with a maximum balancing current of 5A, addressing issues associated with traditional active balancing methods, such as misbalancing, circuit complexity, high costs, and poor electromagnetic compatibility. The hardware has undergone reliability testing, including electrical load, environmental load, mechanical load, EMC testing, and real vehicle testing, while the software development is based on AUTOSAR's layered architecture, enhancing development quality and efficiency.

In 2016, Ganfeng Lithium established Jiangsu Ganfeng in East China, focusing on the production of power batteries for engineering machinery. Since then, it has continuously accelerated capacity upgrades. By 2024, Jiangsu Ganfeng has added efficient automated square aluminum shell module and energy storage box pack production lines, achieving an annual production capacity of 100,000 battery systems. With ongoing technological innovations, Jiangsu Ganfeng has expanded its product line to include new items like standard C/G boxes, CCS modules, and BDU, broadening its offerings from low to high voltage modules and systems. The company is also committed to optimizing communication and power wiring standards while deepening the development of high-voltage BMS products and integrating more cloud platform functionalities to lead industry upgrades. Today, its lithium-ion power battery systems for industrial vehicles have entered the supply chains of several industry leaders, and high-voltage project products have been equipped in vehicles and supplied in bulk, achieving electrification across multiple application scenarios. The company ranked first in national market share in 2023.

During the celebration, leaders from China Longgong and agents from across the country witnessed this milestone moment together. "Jiangsu Ganfeng has grown into a pioneer in the electrification iteration of the engineering machinery field, thanks to our safe, efficient, clean, and intelligent product quality. From 1 to 100,000 units, we have consistently focused on independently developing our battery management system; from 1 to 100,000 units, we have resolved issues related to balancing errors and compatibility, ensuring excellent and stable product performance; from 1 to 100,000 units, we have compressed the time from demand to delivery to as short as 7 days, demonstrating the 'Ganfeng Speed.' Today marks the rollout of Jiangsu Ganfeng's 100,000th power battery system and the beginning of our goal to sell 1 million power batteries," said Jiang Jinsong, General Manager of Jiangsu Ganfeng, expressing his hopes and confidence in future development.

During the celebration of the 100,000 units rolling off the production line, a three-day "Jiangsu Ganfeng Longgong Dealer TTT Training" conference was also held. Jiangsu Ganfeng collaborated with a team of experts from China Longgong to showcase their technical strength and product advantages through discussions on technological innovation, cutting-edge product displays, and training exchanges, creating a platform for learning and communication. During the training, top technical teams from the fields of lithium batteries, BMS, motors, electronic controls, and chargers took turns presenting, ensuring that agents could understand, learn, and apply every detail discussed.

In terms of lithium battery product technology, Jiangsu Ganfeng's technical team analyzed key factors affecting battery cycle life, focusing on battery materials, optimization strategies for battery management systems (BMS), and innovative applications of thermal management technology. The technical team detailed how Ganfeng Lithium's BMS utilizes advanced end-cloud integration technology to achieve "one vehicle, one strategy," ensuring efficient collaboration of the power system. In terms of after-sales service, we launched "Eight Firsts" precise services, integrating "one-on-one online support, on-site quick repairs, customized training, and professional maintenance" to ensure worry-free after-sales support.

The technical team also shared how to monitor battery health and extend battery life while reducing maintenance costs through active balancing technology. Considering the unique application of power vehicles in engineering machinery, the technical team and experts from Longgong discussed the performance of lithium batteries in extreme environments and safety measures, emphasizing the multiple protection mechanisms and strategies of the BMS in charging and discharging, fault warning, and overcurrent protection, ensuring stable operation of new energy machinery vehicles under various working conditions.

Recognizing the importance of practical application, the training included hands-on practice sessions. In Jiangsu Ganfeng's modern production workshop, participating agents operated under expert guidance, simulating processes such as fault diagnosis, component replacement, and routine maintenance of new energy forklifts.

As the penetration of new energy engineering machinery vehicles continues to increase, Ganfeng Lithium will focus more on the actual needs and pain points of industry customers, leveraging its core advantages driven by technological innovation to meet new customer demands with exceptional new technologies, products, and services. Together with partners like China Longgong, we will inject strong momentum into the comprehensive electrification transformation of engineering machinery vehicles, opening a new breakthrough in green development.

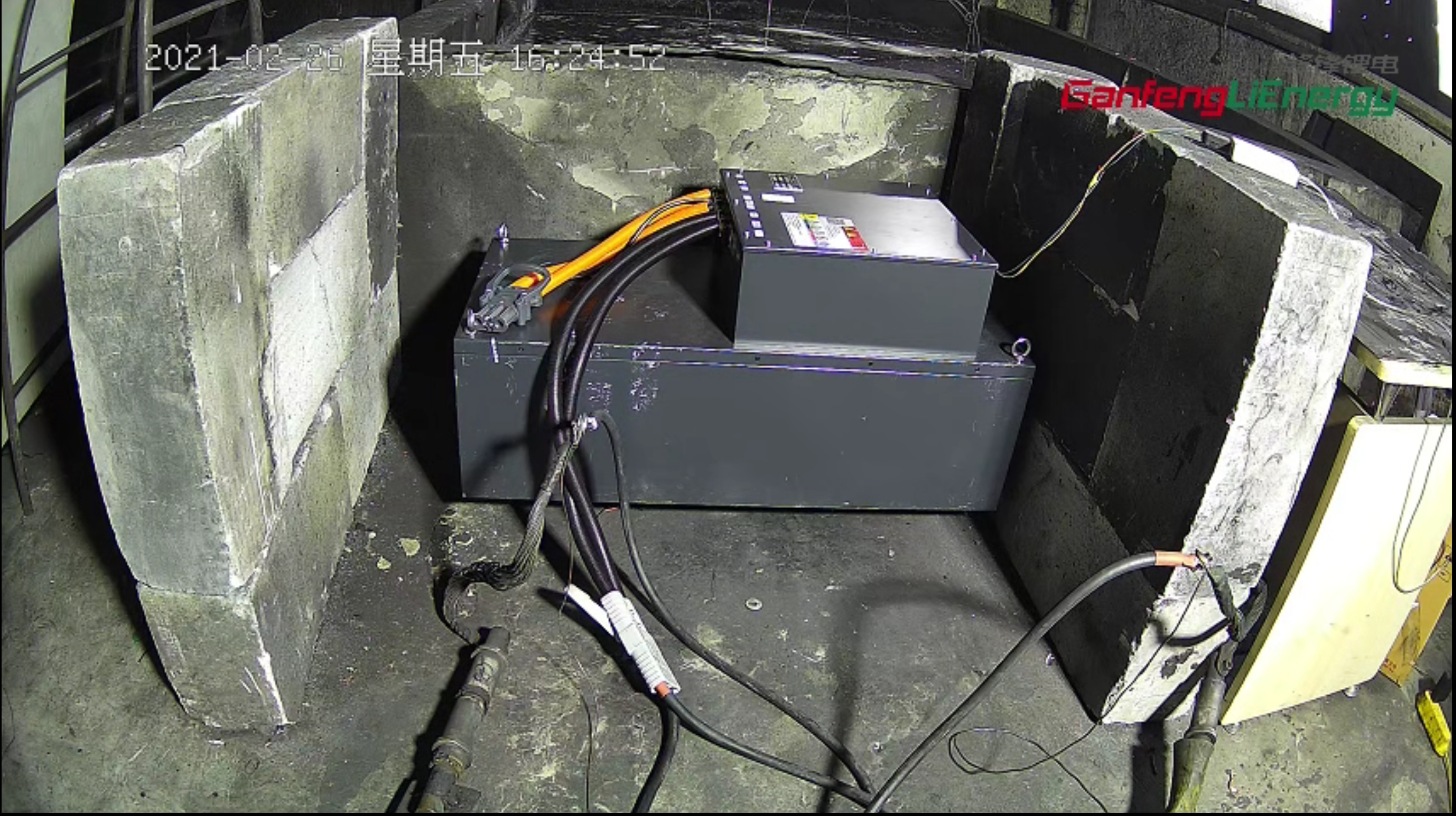

Ganfeng Lithium Battery Passed the Short circuit test

Ganfeng Lithium Battery Passed the Short circuit test Ganfeng Lithium Battery Passed the Thermal Runaway Test

Ganfeng Lithium Battery Passed the Thermal Runaway Test Ganfeng Lithium Battery Passed the Fire Test

Ganfeng Lithium Battery Passed the Fire Test Why use lithium batteries instead of lead-acid batteries?

Why use lithium batteries instead of lead-acid batteries? Questions about Forklift Lithium Batteries

Questions about Forklift Lithium Batteries Ganfeng Lithium's Goulamina project's first phase crushing production line completed ...

Ganfeng Lithium's Goulamina project's first phase crushing production line completed ... GanfengLiEnergy Battery won the title of Top 10 Chinese Energy Storage ...

GanfengLiEnergy Battery won the title of Top 10 Chinese Energy Storage ... Jiangsu Ganfeng's 100,000th Engineering Machinery Power Battery System Rolls Off ...

Jiangsu Ganfeng's 100,000th Engineering Machinery Power Battery System Rolls Off ... GanFengLiEnergy Showcases Multiple Innovative Energy Storage Products at WBE2024

GanFengLiEnergy Showcases Multiple Innovative Energy Storage Products at WBE2024